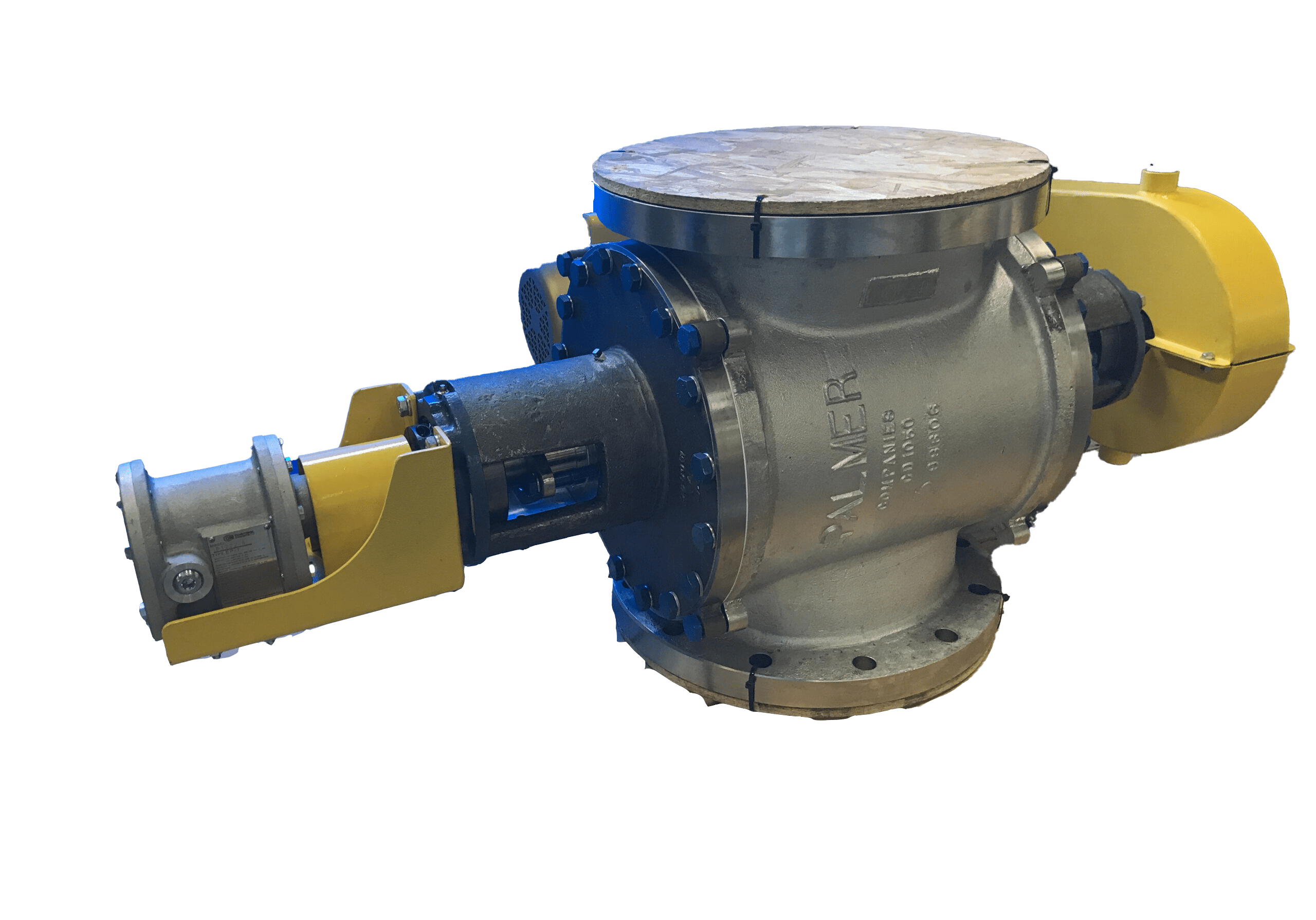

ROTARY AIRLOCK VALVES

Rotary Valves Ready For The Harshest Environments.

Palmer has over 20 years of experience helping our customers extend the useful life of your rotary airlocks, with a focus on maintaining the precise clearances and tolerances between body casting and blades.

New Valves

Retrofit your old rotary valve with Palmer’s Extreme Duty Rotary Valve and experience a top tier design that outlasts OEM models 4 to 1.

All parts of the valve are heavier and stronger, including interior surfaces and the seal protection layer.

OR

Rebuilt VALVES

Not ready to retrofit? REBUILD your worn valve to OEM clearances, and OUTLAST the original OEM design.

Send your old valve to us for a rebuild service today. Palmer will evaluate your existing valve, and provide you with a FREE no-obligation quote for the most effective solution for your application.

Rotary Airlock Modification Packages Include:

Re-machine body casting to remove gouges and signs

of wear

(Optional: Apply HVOF Hardfacing)

Replace or repair shaft and blades

(Optional: Apply HVOF Hardfacing of blade tips)

Sandblast and paint

Replace all seals, o-rings, and bearings

Rotary airlock metal options

All components include Hastelloy, Inconel, Stainless Steel, and more, to meet your application specifications.

Are you performing these critical Rotary Airlocks Maintenance Tasks?

PLANT SHUTDOWNS &

AFTER-HOURS EMERGENCY SUPPORT

Certified Professsionals

Certified Professsionals

Trusted by Industrial Partners ...

They are great people to deal with high quality workmanship

- Mike Corbitt

Get A Quote