HVOF THERMAL SPRAY & HARD FACING in Mississippi

The Premier HVOF High Performance Coating Service In The Southeast.

High Performance Coatings

Are you struggling to balance tight short-term budgets with the long-term demands of equipment maintenance and performance? Before replacing costly wear parts, connect with Palmer Tool to explore how HVOF or PTA technology can significantly extend the lifespan of your components. At Palmer Tool, we deliver advanced HVOF coating solutions across Mississippi for industries that rely on surfaces built to perform under pressure.

Our expertise spans thermal spray technologies, plasma spray systems, and specialized coatings built to defend against abrasion, chemical exposure, and corrosion. As a leading provider of custom coatings and precision finishes, we apply high-performance materials to a wide range of metal parts. From thermal-resistant overlays to durable wear coatings, we engineer solutions that add value and strength where it matters most.

We help clients boost part reliability, enhance surface protection, and minimize the effects of wear and tear. With deep experience in spray coatings, carbide technologies, and precision machining, Palmer Tool is a trusted partner for aerospace, defense, energy, and manufacturing operations throughout Mississippi.

HVOF &

THERMAL SPRAY

Across Mississippi and the greater Southeastern region, companies rely on Palmer Tool for dependable High-Velocity Oxygen Fuel (HVOF) coating solutions. HVOF is a cutting-edge thermal spray method used to enhance surface durability and extend the operational life of parts by shielding them from abrasion, corrosion, and general wear. Industries that see consistent value from HVOF applications include power generation, oil and gas, mining, chemical manufacturing, cement and asphalt production, steel processing, pulp and paper facilities, hydraulic systems, pneudraulics, rotary airlocks, recycling equipment, and many other heavy-use sectors.

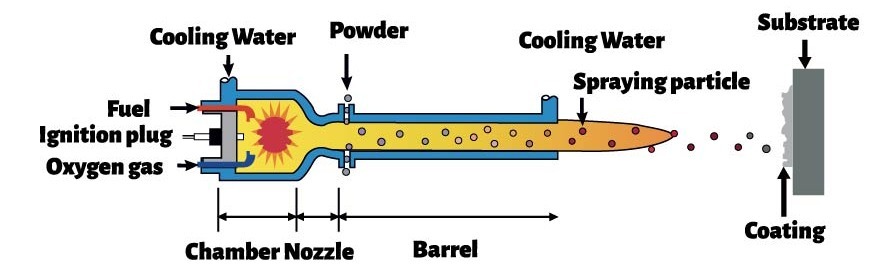

The HVOF process involves feeding a mixture of fuel and oxygen into a combustion chamber, where they are ignited and continuously combusted. The resultant hot gases flows through a converging–diverging nozzle and enters a straight-walled barrel section. A powder feed stock is then injected into the gas stream where it is accelerated through a barrel. The stream of hot gas and powder exits the barrel with a jet velocity exceeding Mach 3. The resulting jet stream is sprayed directly onto the surface of the component, where it begins to deposit as the powder embeds into the substrate. The tremendous kinetic energy of the powder impacting the surface results in low porosity, high bond strength, compressive residual stress, and relatively low processing temperatures.

This allows for temperature sensitive materials such as high strength steels, titanium alloys, and high strength aluminum alloys to be coated without losing their material properties. HVOF coatings range in thickness from 0.1mm – 0.8 mm (0.030″) or more and offer the benefits of extreme wear and corrosion resistance. Common coating powders include Stellite, Colmonoy, Tungsten-Carbide, Chrome Carbide, Stainless Steels, Inconel, Triaballoy and many other alloys with hardness values ranging from 35 HRC (350HV Vickers) to 71.5 HRC (1200 HV Vickers).

HVOF applied Tungsten Carbide is the chosen coating process to replace Electrolytic Hard Chrome Plating for civilian and military aerospace applications. HVOF coatings may also be ground and superfinished to meet all bearing and seal surface finish requirements.

Many industrial applications benefit from Plasma Transferred Arc (PTA) welding, including sectors like chemical processing, dry material handling, mining, power plants, oil and gas, cement and asphalt production, steel manufacturing, pulp and paper facilities, particle size reduction, recycling operations, rotary airlocks, and other rotating machinery components. PTA welding is a specialized method that deposits hard-facing layers on metal surfaces to enhance wear and corrosion resistance.

This hard-facing can be performed using superalloy materials, available in either wire or powder form, such as Stellite 6 and Colmonoy 88. Beyond traditional hard-facing, the process can also apply softer alloys and carbide-reinforced composites to achieve different results, such as better mechanical durability, improved wear resistance, reduced galling, and heightened protection against corrosion.

PTA welding relies on a high-density plasma arc, formed by ionizing argon gas as it passes through an electric arc, which acts as a protective shield. At the same time, a second electric arc—the transferred arc—supplies the necessary heat to melt both the substrate and the added filler material.

By throttling the transferred arc, the plasma column reaches extreme temperatures between 14,000°F (8,000°C) and 32,000°F (18,000°C). As the plasma passes and the molten materials solidify, a strong metallurgical bond forms between the base material and the overlay. Thanks to the constricted and highly focused nature of the plasma arc, the heat is localized, promoting full fusion of the overlay while minimizing thermal impact on the part itself.

PTA is especially advantageous when working with alloys that are too hard to be manufactured into wire form, including cobalt-based and metal matrix composites. Compared to laser welding, PTA is generally more cost-effective, with lower equipment and operating expenses. It also tends to outperform GTAW or TIG welding for similar applications. The process introduces less heat, enabling thinner overlays while maintaining high-quality properties—and powdered alloys are often more affordable than their wire counterparts.

The ability to produce low dilution, low porosity, and thin overlays allows PTA welding to deliver higher-quality results, using less material and with significantly reduced thermal distortion to the base metal.

Advantages of Plasma Transfer Arc Welding over other hard-facing processes include…

Limited heat addition to base metal (due to constricted and columnar welding arc combined with high working speed)

Maintain structural quality and metallurgic homogeneity of base metal

(controlled penetration, with precise positioning of weld deposits on a single pass)

High working speed (often 2X – 3X faster than MIG or TIG) reduces heat addition to base metal and lowers operating cost

Better wear resistance due to harder, tougher coatings

Improved corrosion protection due to less porosity

Advantages of HVOF spraying over other thermal spray processes include…

Higher density denser coatings with minimal porosity thanks to faster particle impact during application

Higher density stronger adhesion to both the base material and within the coating layer itself

Higher strength bond lower oxidation levels as a result of reduced exposure to high temperatures during flight

Lower oxide content due to less in-flight exposure time

Retention of powder chemistry due to reduced time at temperature

powder sizes

Compressive residual stress ensuring coating integrity in high stress applications

Better wear resistance due to harder, tougher coatings

Higher hardness due to less degradation of carbide phases

Improved corrosion protection due to less porosity

Coating Services for Aerospace, Manufacturing, and Industrial Equipment

Palmer Tool delivers advanced coating solutions for industries that rely on durable, high-performance parts. From aerospace assemblies and oilfield equipment to turbines, valves, and pump housings, we help extend the life of critical components exposed to abrasion, heat, and chemical damage.

Our thermal spray and plating services are used to safeguard essential machinery and boost overall efficiency. Operating from an ISO-certified facility, we handle both custom and high-volume production with precision, meeting exact specifications and delivering consistent, reliable results. We service all of the cities in Mississippi: Southaven, Olive Branch, Vicksburg, Hattiesburg, Poplarville, Gulf Hills, Belzoni, Pascagoula, Centreville, Booneville

PLANT SHUTDOWNS &

AFTER-HOURS EMERGENCY SUPPORT

Certified Professsionals

Certified Professsionals

Trusted by Industrial Partners ...

They are great people to deal with high quality workmanship

- Mike Corbitt

Get A Quote