Hard Facing Benefits

Hard Facing conveys two primary benefits… dimensional restoration, and wear/abrasion resistance. Among the customers who can benefit are petrochemical & chemical, mining, steel, power generation, valve engineering, and the marine industry. Hardfacing is typically applied for controlling abrasive wear, such as that encountered by mill hammers, digging tools, extrusion screws, cutting shears, earth-moving equipment, ball mills, crusher parts, rock/coal pulverizer, valve seating surfaces, undercarriage parts of tractors, high-performance bearings, auger flights, shovel teeth, rock drill bits, dies and rolls in steel industry, and pump parts.

Hard Facing by Weld Overlay (Plasma Transfer Arc Welding)

Weld overlay Hard Facing (or Plasma Transfer Arc Welding) is a welding process where the filler metal and a small amount of the base metal are molten and are bonded metallurgically. The weld overlay Hard Facing produces hard and thick coatings with excellent bonding between the Hard Facing material and the base metal. Usually, the weld overlay Hard Facing involves a buildup process, involving the addition of weld metal to a base metal surface for the restoration of the component to the required dimensions. The buildup alloys are not designed for wear resistant but to restore the worn part to its original dimensions and to provide adequate support for subsequent layers of Hard Facing metal.

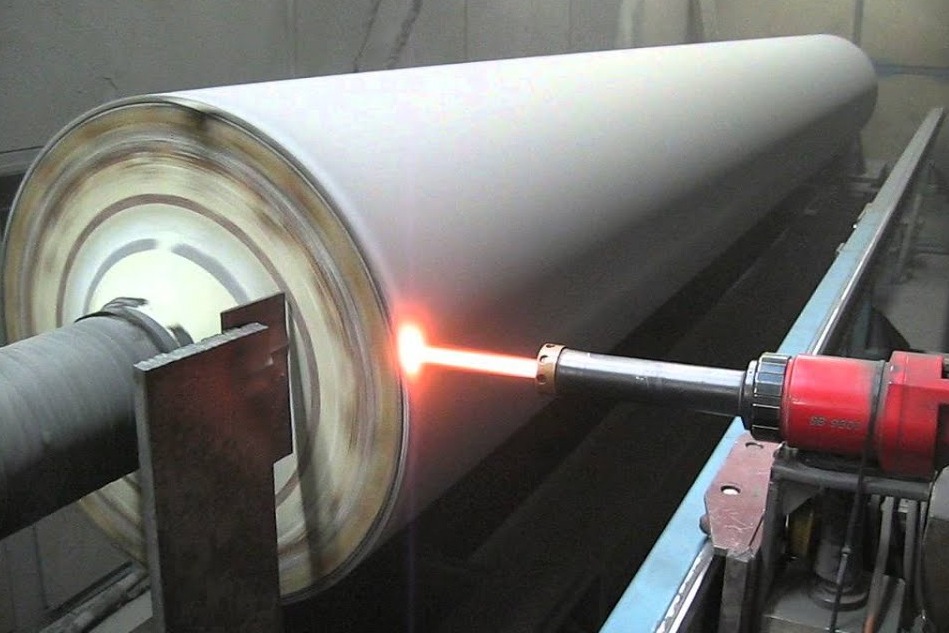

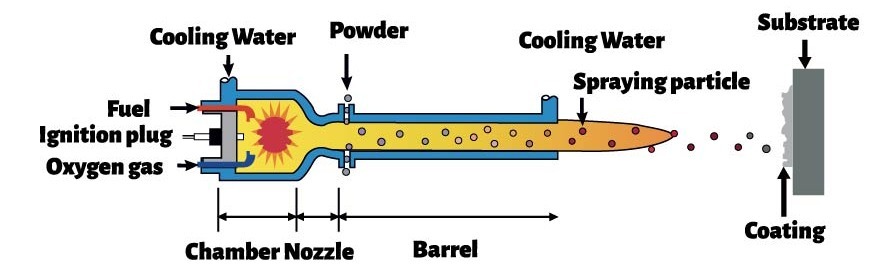

HVOF Thermal Spray for Hard Facing

Thermal spray Hard Facing involves spraying a metallic powder onto a prepared substrate to form a thin coating. As the powder is fed through the spray unit, the particles are heated to a molten state and propelled by a stream of compressed gas onto the substrate. As the particles strike the surface at speeds exceeding Mach 3, they flatten and form thin platelets that confirm and adhere to the irregularities of the prepared surface and to each other. They cool and accumulate, particle by particle, into a cast-like finish. Compared to weld overlay, thermal spray processes are mainly applied for thin and hard coatings with minimum work distortion and result in a purely mechanical bond between the Hard Facing material and the base metal.

Palmer Can Help You With Hard Facing and Thermal Spray

Are you tired of continuously replacing your process components time and time again? Do you find yourself “caught between a rock and a hard place” of juggling your short-term budget limitations vs maintaining your equipment with a long-term “cost of ownership” approach? Do yourself a favor – don’t replace your high-wear components before FIRST speaking with Palmer Tool about the potential benefits of HVOF or PTA to EXTEND the service life of your equipment.